Precision cutting using a hand-held circularsaw.

The circular saw guide and cutting grid are stored against walls when not in use. The grid is so useful however, that mine is set up more often than not.

Id like to know who it was that decided that plywood was best sold in 1.2 m by 2.4 m sheets. Ive always thought that it was a practical joke in questionable taste to take such a wonderfully useful woodworking material and manufacture it in sheets that are bigger than most woodworkers.

Sheet materials are much larger than most woodworking machines. They can’t be safely cut on a table saw of garden variety without first cutting them into smaller pieces. Consequently, making precise cuts in sheet goods is a two-step

process for most woodworkers. The first step is to cut the sheets into manageable size with a circular saw. Next, you will trim the pieces to the exact dimensions using a table saw. These expensive tools can be purchased as a panel saw, or as a sliding table for table saws with high-end features. And even if you can afford them, do you have space to use them? A panel saw, for example, takes up an enormous amount of wall space that most of us dont have. I prefer to keep my workshop’s walls as God intended, with unfinished projects hung from floor to ceiling.

Making a Circular Saw Guide

This problem is easy to solve, it’s affordable and space-saving. With an ordinary circular saw, you can make precise cuts in plywood or other sheet materials using a jig. This jig relies on the straightness and dimensions of all plywood pieces.

The factory edges are the outside edges of a plywood sheet as it arrives from the manufacturer. They are too rough to use in assembly, but they are usually dead straight. It is a good idea, therefore, to ensure that each piece of plywood has a factory edge before you start to cut it on the table saw. Most craftsmen begin trimming operations by guiding this factory edge along the table saw rip fence this creates another straight edge.

Instead of using the factory edge as a guide to trim the plywood on a table saw, I skip the trimming altogether and use a factory edge to guide a circular saw. You will need a guide for your circular saw.

After measuring the plywood and marking the beginning and end of the cut, align the base of the saw guide with the marks. The saw guide should be placed on the safe side of the cutting path. The clamps’ tommy bars must point down. The circular saw may be impeded if the bars stick up.

Choose a sheet of cabinet grade

After the glue has dried, clamp the sawguide to a longboard. Mount a high-quality carbide-tipped combination blade on your circular saw. This is important! A precision blade is required to make precise cuts on any saw. Place the saw’s shoe on the base, with the edge facing the guide. The saw motor should overhang the guide. The base should be cut so that the distance between the guiding edge and the base edge is equal to the distance between the edge of your shoe and the saw blade. As you’ll see, this makes it easy to prepare for a cut.

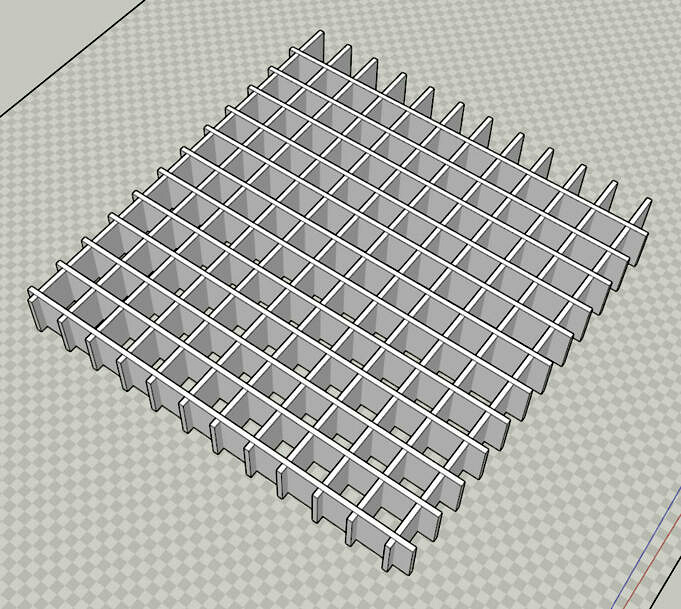

Making a cutting grid

You should make a second jig, a cutting grid, before you start cutting. This will allow you to support the plywood properly while you lay out the pieces and then saw them. My grid consists of two knock-down sawhorses. The horizontal beams of these sawhorses are notched to hold ordinary 8-long 2 x 4s. When set up, the top edges of the beams are flush with the top edges of the 2 x 4s. This arrangement supports a sheet of plywood of any size edge-to-edge and end-to-end to keep it from sagging.

Make the cut with the circular saw motor hanging over the guide this arrangement provides the most support for the saw and keeps it from tipping.

This grid is one of those truly indispensable jigs. Once I made one, I couldnt imagine how I did without it. Not only is it useful for sawing, it also makes a great assembly table for large projects. On occasion, Ive used it as a clamping grid for odd-shaped assemblies. And I always seem to employ it as a drying rack when Im finishing a project. Even though I made the cutting grid to break down, it spends most of its time set up.

Making a Cut

Place the plywood on the grid. Rest the plywood on the grid if it is small. Measure the plywood and make two marks to indicate the beginning and end of the cut. If you draw a line from these marks to indicate the beginning and end of your cut, there will be a save side (the part you are going to save) as well as a waste side. The saw guide should be placed on top of the plywood. Align the marked edge with the trimmed edge. Clamp the guide to the plywood with two small (5 cm) C-clamps.

As you cut, adjust the depth of the circular saw to ensure that the blade extends just 1/41 cm to 1/20cm below the plywood’s underside.

This is a must-have because the saw can eat through the top of the grid. But it wont weaken the supporting structure as long as the cuts are shallow. Tip: When cutting across the surface grain of a sheet of plywood, you can prevent the veneer from splintering or feathering by scoring along the edge of the base with a utility knife before you make the cut.

Just how accurate is this system? It is very accurate, which many people will find surprising considering the simplicity of the tools and jigs involved. I’ve built cabinets for two kitchens, as well as numerous shelving systems, using a circular saw. Im convinced that I couldnt do any better with a sliding table or a panel saw. PWM

Click below to download a PDF of this article, with measurements and drawing for the cutting grid:EnglerCuttingGrid

Recommendations for Product

These are the tools and supplies we use every day in our shop. Although we may be compensated for sales made through our links, these products have been carefully chosen for their utility and quality.